Postagem relacionada

O que é seleção de comprimento de onda (365–405 nm)?

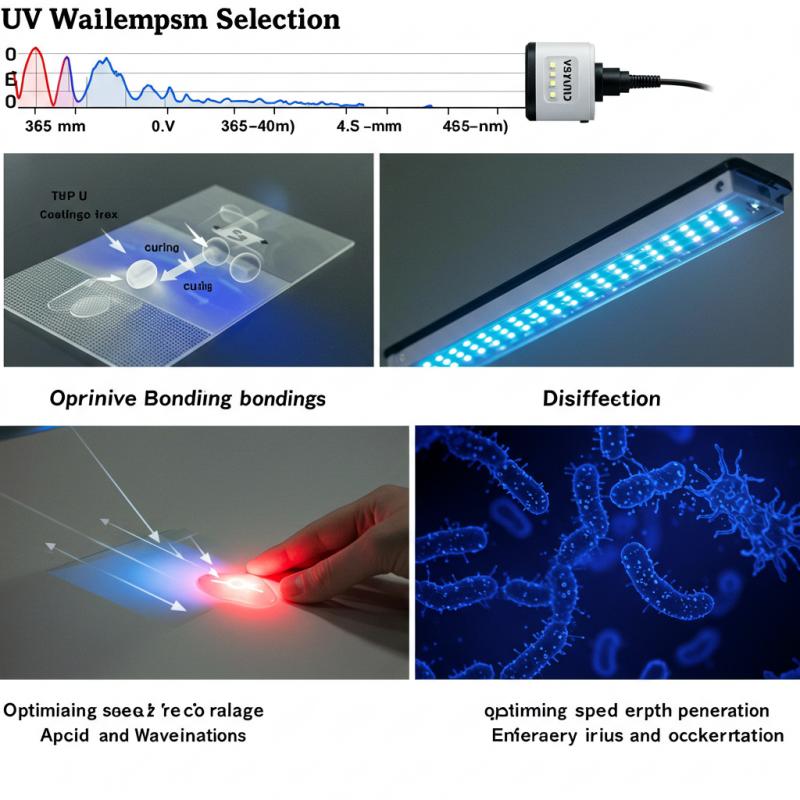

2025-07-22To explain wavelength selection (365 – 405 nm) requires an understanding of the UV LED Systems, especially the phenomenon of light scattering. Here, light scattering pertains to the distance between waves of light. Thus, gaining precise energy, association with certain surfaces, and 365 – 405 nm interactions with UV rays is prime for many engineering and medical applications. In this context, photo initiators are activated by absorption of UV energy, leading to fundamental chemical processes such as:

• Coating and adhesive photopolymerization

• Bonding at surfaces in optics and electronics.

• Sterilization in air and water systems (not UV-C)

• Curing precision in PCBs

Each photonic energy unit is associated with specific conditions relating to curing depth, adhesion, reaction duration, and thermal profile. For instance, 365nm penetrates more deeply, whereas 405nm is cooler and gentler on more fragile materials. Choosing a wavelength within Seleção de comprimento de onda (365–405 nm) is critical as it enhances the efficacy and compatibility of materials with the UV curing system, as well as the architecture of the system.

Why This Range? Advantages of the 365–405 nm Interval?

This band is strategically positioned in the middle of UV-A and borders on near-visible light spectrum regions, hence it is useful for many applications of UV LEDs. The range achieves the optimal intersection among the three factors: exposure to and efficiency for photochemical processes, object curing, and safety for the treated surface. This is how we analyze it:

- 365 nm

• Produces higher energy photons while emitting shorter wavelength ultraviolet radiation.

• Boosts thorough curing, especially when working under clear coatings.

• Best suited for high-strength optical bonding, adhesives, and coatings.

• Oversees swift photopolymerization for tasks requiring extreme bursts of energy.

- Between 385 – 395 nm

• Provides a balanced middle ground between depth of curing and processing speed.

• Prevalent in the assembly of medical devices, electronics, and industrial coatings.

• Compatible with nearly all commercial photo initiators.

- 405 nm

• These emissions are closer to the visible spectrum, which makes them gentler on sensitive surfaces.

• Slightly heats thermally sensitive components like plastics and circuit boards.

• Safe and consistent outcomes with minimal risk of damage to the materials.

Careful consideration of positioning within the range of 365 – 405 nm UV LED spectrum will likely yield optimal results and extend equipment life.

Applications Based on Wavelength

Understanding how some industries leverage particular UV LED wavelengths can aid your choosing strategy.

Medical Devices (385–405 nm)

- Ideal for the assembly of thin, delicate plastic components.

- Curing with precision without inflicting thermal damage.

- Guarantees uncontaminated, clean joints.

Packaging & Printing (395nm)

- In roll-to-roll methods, curing is fast and efficient.

- Compatible with photo initiators used in manufacturing.

- Inline production with little delay is possible.

Electronics (365–385 nm)

- Applicable for potting and sealing of PCBs and optical fibers.

- Offers good bond strength with low deformation.

- Reduces the risk of damaging sensitive circuits due to excessive heat.

Lab Equipment (365 nm)

- Best bonded with glass, quartz, and certain plastics at these wavelengths.

- Attains clarity and high structural integrity.

- Shields from yellowing and other impurities.

UV-A LED Science: Bleaching, and Why Nanometers Matter

Different energies are carried by each LED UV wavelength.

• 365nm ≈ 3.4eV (stronger)

• 405nm ≈ 3.06eV (weaker)

Changes in eV will elicit a particular response from photo initiators. Stronger photo initiators8 instigate deeper reactions while milder ones tend to be safer for sensitive surfaces.

Calibration Methods for Ultraviolet Laser Diodes Emitting Light of UV Wavelengths

Every single detail is critical in sophisticated systems based on ultraviolet light (UV) emitting diodes (LEDs). Before operational lifetime and refractive index shifts within the system are considered, the curing quality needs to be consistent. Calibration tools make it possible to achieve high-performance three-dimensional UV printers by enabling precise firing of each UV LED at the needed wavelength and power for steps like photopolymerization, adhesive curing, or optical bonding.

- Verification of the accuracy of wavelengths emitted by UV LEDs requires the use of spectroradiometers. These devices capture the emission spectrum and verify whether a system is emitting required nanometers, be it 365nm, 385nm, 395nm, or 405nm. This is critical for matching the output of LEDs to the absorption peaks of the photo initiators for optimal reaction efficiency.

- In addition, UV power meters also measure irradiance (mW/cm²) to maintain the consistency of UV energy, which affects the curing speed, depth, and bond strength. Meeting these standards in high-throughput processes is critical, as even a minor dip in performance is unacceptable.

- Optical filters assist in powerful scrutiny and precision targeting in high delicacy electronics and optics, as they determine the geometry of the beam, its intensity, and even its spectral novelty within focused regions of ultraviolet LEDs

- Lastly, the calibration software is critical in monitoring LED aging and the depreciation in output. As with any technology, UV LEDs have particular operating windows within which they are most efficient. Planned maintenance checks uncover hidden glitches long before they become problematic.

Environmental & Safety Considerations

For ecological safety, the 365–405 nm range comes with a unique benefit. Compared to conventional UV lamps, which utilize mercury, these emit zero mercury, thus becoming completely exempt from any mercury waste, hazardous waste, and emissions of relevant legislation like REACH and RoHS compliant regulations.

- Due to the lack of emission of 280 nm (UV-C), these UV LEDs pose no ozone risk, hence are safe for enclosed environments like offices, medical laboratories, and can be safely built into consumer goods. Also, the lack of emission below \(280nm (UV-C)\) means no generation of ozone or biologically harmful emissions associated with ionizing radiation (UV).

- These UV lamps contain critical advantages as well. UV radiation in the 365—405 nm range is non-ionizing radiation, which means that, under customary use, there is no possibility of damaging DNA or cellular structures. This feature is advantageous for healthcare instruments, electronic devices, optical systems, and laboratories where the safety of staff and the integrity of sensitive materials are priorities.

- The absence of UVC radiation exposure, minimal thermal load, and low emission rates all contribute to UV LED Seleção de comprimento de onda (365–405 nm) being both precise and eco-friendly and legally compliant, which is indispensable for modern industries.

Conclusão

As in any discipline, UV LED wavelength selection must ensure that the integration of light at 365 and 405 nm is balanced with certain parameters. There needs to be consideration of chemistry, force, and procedure, as well as design and application. At A CONCLUSÃO, we guarantee mastery of the UV LED spectrum, photo initiators, and their ultraviolet compatibilities, as well as OEM customizable fixed and tunable bespoke wavelengths. Startups and even global OEMs will make the right decision with absolute certainty and efficiency on wavelength selection because our unwavering support provides steadfast guidance.