Postagem relacionada

O que é um dispositivo UV compacto?

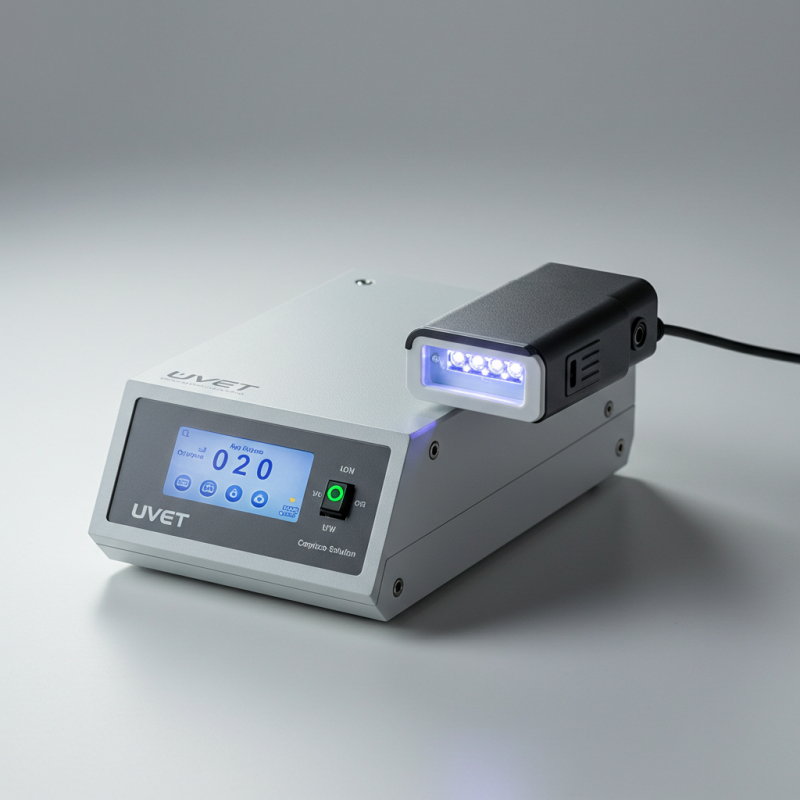

2025-07-22Just like its name suggests, a compact UV device is lightweight, easily portable, and can be powered by a battery or portable charger. Moreover, the device can perform multiple functions, such as curing adhesives, sterilizing surfaces, and disinfecting air or water. Thus, making the device multifunctional. Depending on the field of work, the systems can be tabletop UV curing devices, portable UV LED units, or handheld ultraviolet lights.

Due to their size, compact handheld devices tend to lack high performance; however, this is not the case as these portable units make use of high-performance UV LED technology, which ensures compactness coupled with power.

UV LED Curing Device: The Most Efficient Compact UV Device

UVET’s UV LED Curing Device is known as the best compact UV device due to its precision and reliability. Its ring-type design ensures that uniform UV irradiation is delivered within a controlled area of Φ25–Φ50mm, which is perfect for focused curing processes. Moreover, the device is capable of emitting wavelengths of 365nm, 385nm, 395nm, and 405nm, thus catering to different UV-sensitive materials and Photo initiators. It provides an excellent answer for industries with strict requirements for cleanliness and consistency, such as electronic assembly, medical device manufacturing, and optoelectronics.

Key features:

- Targeted Irradiation Area (Φ25–Φ50mm) – Focused beam for pinpoint accuracy

- Multi-Wavelength Options – Supports multiple UV LED spectrums for material compatibility

- Water-Cooled System – Maintains stable output while managing heat effectively

- Instant On/Off – Saves energy and improves cycle time

- User-Friendly Interface – Easy setup and operation require minimal training

- Low Heat Emission – Especially suitable for protective surfaces such as medical devices and plastics

Industrial Advantages:

- This small-sized UV device is designed for very accurate industrial applications. In electronics, it aids in bonding, sealing, and micro-assembly of circuits as it provides fast curing without overheating. In medical manufacturing, it provides strong adhesive bonds for biological components such as catheters, valves, and diagnostic pieces while preserving biological materials. In optoelectronics, it allows the accurate positioning and mounting of lenses, filters, and photonic sensors into position without optical distortion or damage.

- Beam uniformity is one of the most remarkable features. Because of the ring-type design and precision optics used on the device, uniform exposure to UV light is ensured on all surfaces, whether simple or complicated. This allows finely tuned and repeatable high-quality curing, which is critical in automated production systems.

- Designed for both the industrial and laboratory settings, checking off the boxes for compactness, modularity, ease of integration, and long operational life, UVET’s curing device is unparalleled. When it comes to your accuracy and reliability requirements, this UV LED system has you covered, whether you’re prototyping in a lab or optimizing workflows in an assembly line.

Advantages of Compact UV Technology

1. Portability and Versatility

Cleanrooms, dental offices, and even factory floors are all capable of accommodating compact UV systems, making these devices handy in mobile scenarios and constrained work environments.

2. Energy Efficiency

Operational costs and heat generation are reduced with embedded UV LED technology, which gives these devices an edge over others because of their heightened power efficiency.

3. Safety and Compliance

Being mercury- and ozone-free as well as compliant with international regulations such as RoHS and REACH makes these devices safe to use.

4. Rapid Curing and Sterilization

Curing adhesives or sterilizing surfaces can be done swiftly. Compact UV systems can expose materials to shortwave UV radiation to instantly cure adhesives and kill 99.9% of bacteria.

5. Low Maintenance

Compact systems that utilize LEDs and have fewer moving components require less maintenance, resulting in reduced operational expenditures and increased equipment lifespan.

What You Need to Know: Benefits of UV LED?

Every Dispositivo UV compacto core component is a strong UV LED light source. These diodes emit specific UV wavelengths (between 365nm to 405nm) for different functions:

• 365nm – Deep curing for transparent adhesives

• 385nm – 395nm: Balanced penetration and speed for coatings

• 405nm: Safe for delicate electronics and plastics

Scope of Application

- Medicine and Healthcare Services

Portable UV LED devices are useful in sterilizing surgical tools or air disinfection within the patient’s room.

- Automotive and Aerospace

Best suited for UV curing of confined spaces within dashboards, control panels, and decorative trim.

- Electronics Industry

Compact devices are ideal for UV bonding of optical fibers and PCB components.

- Laboratories and Cleanrooms

Small UV sterilizers retain the capability to keep sterile areas free from bulky equipment.

- Field Service and Remote Work

Handheld UV lights can be taken to remote areas for off-site disinfecting or repairs.

Small Footprint, Large Capability

Today’s ultraviolet light (UV) devices are compact and packed with modern technology. Most modular UV systems are made with interchangeable wavelength heads and UV LED modules, which makes them easy to adapt to different curing and sterilizing applications. The compact systems have built-in control units that enable accurate settings and can be powered by a battery or USB, making them portable and easier to carry.

- Their shape is suitable for cramped spaces, which makes them a wonderful OEM equipment and lab device. Most importantly, they offer unrivaled industrial-grade power and minimal thermal output, making them reliable without harming sensitive machinery.

- These devices are mercury and ozone-free, aligning with health and environmental standards, while the low heat makes them ideal for enclosed spaces or situations where the temperature is a concern. The eco-friendly design makes them suitable for cleanrooms, medical labs, or production lines.

- The offered solutions help ease business in other ways as well; compact UV systems have 10,000 to 20,000 hours of operation, increasing maintenance intervals and reducing energy expenses, thus lowering operating costs. These systems bring value over time. If high-scale production or new devices need to be developed, wouldn’t it be wonderful to have compact devices readily available that provide unparalleled performance?

Important Aspects to Consider

Evaluating the primary technical details of a device will guarantee consistent performance and enduring value. Perhaps the most critical detail is spectral power density. It determines how much ultraviolet (UV) energy is emitted over an area. This will affect both the speed and depth of curing. Devices that have high power density capabilities tend to give faster results. This is particularly important in electronic and optical high-precision manufacturing.

- Beam uniformity is equally essential. The issues discussed previously would result from uneven output from a beam, leading to inaccurate curing or sterilization. A good compact UV system will maintain consistent output across the entire beam area. This enhances the accuracy and repeatability of the process.

- Adjustable intensity levels can be an added advantage. These features allow one to control the UV energy delivered to different substrates or photo initiators, reducing waste. Be mindful of what cooling method is employed. Compact devices can either be air or water cooled. Each has its advantages and disadvantages in regard to performance, size, or where it can be applied.

- Last but not least, calibration compatibility is important. The standard measuring instruments, like spectroradiometers and UV power meters, should be used so that the performance of LEDs can be measured and controlled over time.

Conclusão

Um Dispositivo UV compacto is more than just a space-saving tool. It boosts efficiency, reduces waste, and enhances productivity in a multitude of industries. Their range of applications, from sterilization to curing, is truly remarkable. These devices deliver professional-grade results without requiring much space. Looking to optimize your workflow with advanced UV technology? Visit A CONCLUSÃO and discover a world of compact opportunities waiting for you.